CaF2 Window /Calcium Fluoride optical windows

The windows can be applied on projection system, imaging system, Optical measurement system, IR detector and imaging technology .

Technical Parameters

|

1

|

Material

|

BK7 ,UV Fused Silica, CaF2,BaF2,Sapphire etc

|

|

2

|

Dimension Tolerance

|

+0.0,-0.1mm

|

|

3

|

Thickness Tolerance

|

±0.05mm

|

|

4

|

Surface Flatness

|

λ/10 at 632.8 nm

|

|

5

|

Surface Quality

|

20/10 scratch and dig

|

|

6

|

Angle Tolerance

|

+/-3'

|

|

7

|

Clear Aperture

|

>90%

|

|

8

|

Bevel

|

0.2 mm to 0.5 mm x 45deg

|

|

9

|

Coating

|

Customer's requirement

|

Features:

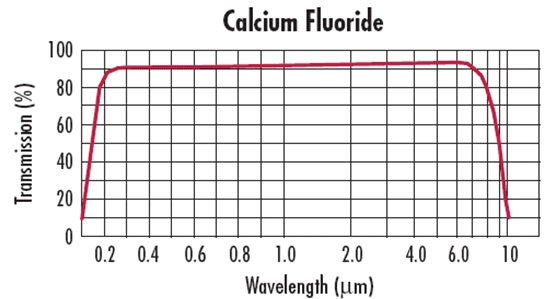

Low cost, a wide range of spectrum, low absorption, high damage threshold, High Transmission UV Grade Calcium Fluoride, Ideal for Applications Ranging from 250nm thru 7µm, Low Index of Refraction.

Applications:

High power laser optics, excimer laser.

Description:

Calcium Fluoride has excellent transmission in the UV, they are often used to make windows from below 150 nm and extending throughout the visible range. The material of CaF2 Windows are relatively soft and somewhat hygroscopic, Polished surfaces are stable and will last several years under normal conditions, so polishing and coating during processing are more critical.

Calcium fluoride is often used in spectroscopic windows and lenses due to its high transmission from 250nm to 7µm. Its low absorption and high damage threshold makes it a popular choice for excimer laser optics. Calcium fluoride's low index or refraction allows it to be used without an anti-reflective coating. The Knoop hardness of calcium fluoride is 158.3. Calcium Fluoride (CaF2) Windows manufactured from vacuum UV grade calcium fluoride are commonly found in cryogenically cooled thermal imaging systems.